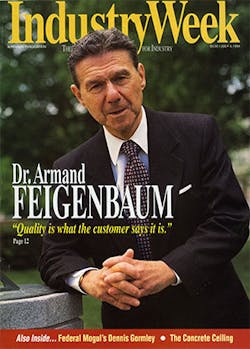

Editor's Note: IndustryWeek has been reviving archived articles of interviews conducted by our editors with the "gurus" of quality -- Deming, Juran, Crosby, and in this article, Armand V. Feigenbaum, who died in November 2014. It was a lengthy, robust conversation, so we have broken the interview into several articles. This is Part 1. The second installment is available at Dr. Armand Feigenbaum on the Cost of Quality and the Hidden Factory. The article originally appeared in 1994.

Often linked with Dr. W. Edwards Deming and Dr. Joseph Juran as one of the three "gurus" who taught quality to the Japanese in the 1950s, Dr. Armand "Val" Feigenbaum is now known as a worldwide implementer of total quality systems via General Systems Co. Inc. (GSC), the Pittsfield, Mass.-based firm of engineers he formed with his brother Donald in 1968.

GSC's work at Tenneco Inc. resulted in quality-cost reductions of $1.1 billion from 1992 through 1993, with the savings continuing in 1994. At Union Pacific Railroad, GSC efforts resulted in measured increases in customer satisfaction, a string of quarter-to-quarter increases in earnings, and quality-cost savings exceeding $500 million since their partnership began in 1988. Other clients include IBM, Citicorp, Ford, Cummins Engine, Toshiba, Hitachi, Renault, Fiat, Phillips, and Pirelli Brazil.

You have to understand that quality problems, like bananas, come in bunches. And if you try to go at them a banana at a time rather than at the stalk, you're going to wind up with a lot of sour fruit.

Beginning his career as an apprentice toolmaker at General Electric Co., Dr. Feigenbaum rose to the position of worldwide director of manufacturing operations and quality control. His work with Toshiba and Hitachi in the early 1950s led to invitations to visit Japan, where he emphasized the broad management themes of customer satisfaction and results-driven quality, mainstays of his company's consulting work today.

Dr. Feigenbaum was also instrumental in initiating the quality movements in Europe and Latin America -- specifically Brazil and Argentina -- in the late 1950s and early 1960s, and is currently an adviser to China's Assn. for Quality Control. His signature text on the principles, practice, and management of quality systems, Total Quality Control (McGraw-Hill Inc.), is in its third edition and has been published in more than 20 languages.

IW: What is your working definition of quality?

Feigenbaum: Quality is what the user, the customer, says it is. That, I think, is the critical starting point. It sounds simplistic, but it's anything but that. If you look at the American companies, or the world companies that succeeded during this economic crucible we've just come through versus those that had a very rough time, you will find the common denominator is their deep understanding of this concept.

The corresponding point is, therefore, if you want to find out about quality you better not merely stay in your office and go through analyses and mental gyrations. You better go through the difficult, agonizing work of talking to the user. The American automobile industry, in its sincerity, believed that the automobile engineer knew more about what you or I ought to be driving than we did. And technically that might be true. But fundamentally, in terms of buyer preference, it's absolutely untrue.

IW: Please explain your concept of total quality control.

Feigenbaum: Total quality control is a way of managing a business to serve the user. Recognizing that in order to achieve it, every part of the company needs to work in a coordinated way to accomplish that objective. Quality is a process. It is not a technical activity. It is not a set of seminars. It is not a set of statistics. It is a fundamental user-requirement to user-satisfaction process that brings every man and woman in the organization· into the service of quality. The emphasis is on "total."

And when I speak about quality, I'm not talking about defects, the reduction of defects, zero or otherwise. That's not what it's about. What total quality control is about is increasing the number of good values that customers receive. That's the differential. Improve the things you do right, don't just cut down the things you do wrong.

IW: Let's talk about managing a company far quality. First, what is the basic responsibility of management?

Feigenbaum: Create proven value for customers, for employees, and ultimately for investors.

Better Quality Improves the Entire Organization

IW: In your book you say that quality is a fundamental way of managing a business.

Feigenbaum: In my early years at GE, I was desperately trying to find a way to do my job better. I tried management by objectives: · it was O.K., but not great. I tried inventory management; it was O.K. I tried psychological testing; it wasn't O.K. What I began to realize was that what we did to make quality better far the user made everything in the organization better.

Now there was nothing logical about it. But progressively I found that if we supported it and if I exposed myself with respect to it rather than just making a speech; if I was the quarterback, the creator of the playbook, and if I was willing to go out on the field rather than just remain in the stands and watch somebody else scrimmage, it would succeed. That, simply, is the responsibility of management. Fundamentally different from a Fourth of July speech to show that our heart is pure for quality. Fundamentally different from a group of seminars. Fundamentally different from cutting off the cat's tail an inch at a time in terms of individual projects, because as you fix this problem a pipe breaking somewhere else creates more problems.

To have a measurement without an implementation in the improvement process is useless.

IW: Does this relate to your concept of silos and islands without bridges?

Feigenbaum: Absolutely. So much of quality attention has been oriented to the issue of improving reliability, and that somehow engineering can do that. We have to find a way to train our people better in the factory. We have to create a way of getting better statistical process control. The problem is that what you wind up with is a group of individual silos in the organization that don't communicate with each other, which improve up to a point but then can't improve anymore. And finally, veteran employees begin to say, "It's just another quality-improvement crusade," all of which died and were buried without autopsy.

Now what that fundamentally means is an abdication of management, because management is passing its responsibilities off to people within the organization. You have to understand that quality problems, like bananas, come in bunches. And if you try to go at them a banana at a time rather than at the stalk, you're going to wind up with a lot of sour fruit.

IW: How does this relate to your concept of results-driven quality?

Feigenbaum: It is central to it. It is central to the improvement of business results. Quality leadership is the single most powerful way to improve costs, to increase customer satisfaction, and to develop human-resource effectiveness. These are the three pillars of business results. Part of the principle is that quality and cost are a sum, not a difference. Partners, not adversaries. And a disbelief in that is still endemic in much of American industry.

IW: How do you go about setting meaningful working objectives for quality?

Feigenbaum: There are three ways in which you can set quality or other objectives.

First, you can do better than you did last year. We made a 7% improvement in quality or costs last year, 8% is O.K. this year. And many companies set objectives that way. That's great until a competitor comes down the pike to blindside you by doing much better. ·

The second way is to counterpunch very quickly. If Fuji comes out with a little faster film, I, as Kodak, am going to come out with one that is equally fast. That means that maybe I can hold my market share. Many companies operate that way, counterpunching. They think it's low risk. They don't reach out to something new. In fact, it could be very high risk.

That gets us to the third way, leading the market by a little bit, really understanding where the consumer is going, what he or she wants, what he or she needs. This is what I mean by continually improving quality service, and it's part of managing the company for quality. This isn't as big a risk as it looks. It's part of quality decision-making in terms of setting objectives. Lead the market by a little bit. It isn't a risk because you are listening to the customer.

Quality and Innovation are Integral

IW: One of Dr. Deming's ideas was that the customer really doesn't know what he wants, that you simply have to innovate. Is that at odds with what you are saying?

Feigenbaum: Absolutely not. It's absolutely true. Quality and innovation are integral. The consumer doesn't know what he or she wants until he sees it, until he can kick it. So part of your way of managing quality is to find the ways and means of doing that quickly, rather than taking years to create something new. One of the strengths of Japanese electronics, which turned out to be a weakness, is the number of models available. There are thousands. But that doesn't mean that they are going to produce all of them in volume. They're letting the consumer make his or her choice. Increasingly, the consumer is buying value, not the iron. They want reliability. They want dependability. That is part of how you can lead with innovation.

IW: What about methodology? For instance, you coined the phrase "what you measure correctly, you can manage correctly. Could you please elaborate?

Feigenbaum: I'm referring not merely to the product or the manufacturing process. I'm talking about the overall management process that you use to achieve quality. The difference in systems effectiveness between leaders versus followers can be as much as three times: 25% or 30% for laggard companies, 90% for leading companies.

IW: These numbers are based on statistical measurements?

Feigenbaum: Rigorous methodology. It's interesting. As I visit people, or people visit here, they bring copies of my books for me to autograph. I surreptitiously look at the pages. There are those that have obviously been soiled versus those nobody has ever touched. And there is a dramatic difference. The difference between the companies that have succeeded versus the companies that have failed is the degree to which the pages on systems and systems engineering have been used.

IW: So, are American companies getting the most out of statistical process control?

Feigenbaum: Statistical process control is only one of literally hundreds of elements that make up quality-systems effectiveness. It has been successful when there's been an understanding that statistics are fundamentally information. And like any other form of information, it is useful only when it is used. To have a measurement without an implementation in the improvement process is useless. That is the swing factor between success and failure for statistical process control.