2013 IW Best Plants Winner: Thermo Fisher Scientific -- Growing a Quality Culture for the Lab

What is the secret sauce that keeps Thermo Fisher Scientific's Asheville plant focused on improvement? The company's dedication to serving science is certainly one important ingredient.

"We know that the instruments we make here are going into laboratories that are finding cures for Alzheimer's disease, cancer and childhood diabetes," says Phil McLellan, director of operations for the facility. "They have a very important role in the work that is changing human lives around the world."

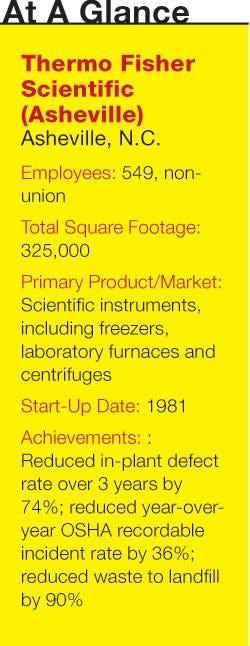

The Asheville site produces 78 different product lines, ranging from ultra low temperature freezers to laboratory furnaces and centrifuges. In 2012, the factory shipped 45,000 units, with 40% of the products exported to Asia and other markets. Much of the work involves building customized products for specialized applications for customers ranging from the Centers for Disease Control and pharmaceutical firms to university-affiliated hospitals.

For example, the ultra low temperature freezers that Thermo makes hold organic tissue samples and each freezer may store $250,000 to $500,000 worth of material. In some cases, the freezers hold samples from a scientist's lifetime of research. "Obviously, the quality has to be bullet-proof," says McLellan.

To meet its quality and production targets in a high-mix, low-volume environment, the Asheville site uses a vertically integrated model, conducting metal fabrication, welding, brazing and painting operations in addition to making components and subassemblies. In 2012, the plant's fabrication department, for example, produced 1.7 million parts out of 110,000 sheets of metal with a first pass yield of 99.43%.

Continuous communication helps keep Asheville on track. Work cells start their shift with a standup meeting. Similar meetings occur later for production supervision and the four value streams, culminating in an 11 a.m. meeting for site leaders. All meetings review recent results and immediate goals while flushing out issues to address for improvement.

Thermo Fisher employs a continuous improvement methodology called Practical Process Improvement (PPI) that is focused on improving safety, material flow and lead time. Plant leaders and employees suggest projects for improvement. The facility completes about 80 to100 kaizens per year, says Tim Hamel, who manages PPI, as well as another 2,000 solo projects done by employees.

Plant leaders agree it is the engagement and empowerment of employees that underlies the progress at Asheville.

"The distance that we have come is just eye-popping," said Jeff Robinson, a 10-year veteran at the facility. "Three years ago, it was really top-down driven. Now, as leaders, we're keeping up with the associates, who are bubbling things up, want to be involved and want to make changes to improve."

Read more about 2013 IW Best Plants winners.

See the IW Best Plants winners at the 2014 IW Best Plants Conference.

About the Author

Steve Minter

Steve Minter, Executive Editor

Focus: Leadership, Global Economy, Energy

Call: 216-931-9281

Follow on Twitter: @SgMinterIW

An award-winning editor, Executive Editor Steve Minter covers leadership, global economic and trade issues and energy, tackling subject matter ranging from CEO profiles and leadership theories to economic trends and energy policy. As well, he supervises content development for editorial products including the magazine, IndustryWeek.com, research and information products, and conferences.

Before joining the IW staff, Steve was publisher and editorial director of Penton Media’s EHS Today, where he was instrumental in the development of the Champions of Safety and America’s Safest Companies recognition programs.

Steve received his B.A. in English from Oberlin College. He is married and has two adult children.