Planning is one of the core functions of supply chain management, and yet by its very nature the concept of an “accurate forecast” is an oxymoron. All forecasts end up being wrong; the key is being able to minimize the errors. That’s far easier said than done, particularly as a skittish economy has led to customers not only becoming increasingly fickle but impatient as well. How can you accurately predict the success of a new-product launch when the marketplace could change dramatically in between design conception and product rollout?

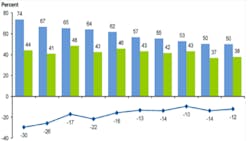

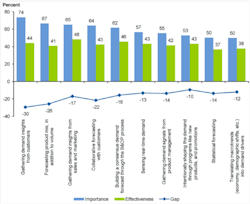

Analyst firm Gartner set out to identify some best practices in demand planning by surveying 240 supply chain experts at manufacturing companies in various industries. As part of that process, they looked at the gap between how important respondents view specific planning tasks and the effectiveness of that task. The largest gap, it turns out, comes in the process of gathering demand insights from customers: 74% of respondents say it’s important, but only 44% say it’s effective.

See Also: Supply Chain Logistics Best Practices

“It is critical that organizations develop the right demand planning process to improve effectiveness,” says Steven Steutermann, research vice president at Gartner. “Without a functioning process, obtaining a consensus-driven demand plan will prove extremely challenging.”

The top three best practices in demand planning, according to Gartner’s research, are:

1. Define the balance between statistical modeling and collaborative forecasting. This helps improve accountability for the forecast, and enables continuous improvement across the organization, Steutermann says.

2. Utilize demand sensing and shaping capabilities. Companies that utilize these capabilities as part of their demand planning processes significantly improve their forecast accuracy. “Organizations must recognize that the demand plan is not a sales or marketing forecast, nor is it a budget,” he points out. “It is a process by which organizations determine the most profitable mix of items that could be sold, balanced by constraints and demand risks.” Demand sensing, in Gartner-speak, refers to collecting and leveraging downstream channel data in supply chain decisions. Demand shaping refers to conscious activities that influence customer demand toward more profitable categories or specific products.

3. Measure forecast accuracy at the item, location and customer level. “Customer or sales forecast accuracy should be measured for continuous improvement and accountability,” Steutermann notes. “The appropriate place to measure for continuous improvement is in the sales and operations planning review process.”

About the Author

Dave Blanchard

Senior Director of Content

Focus: Supply Chain

Call: (941) 208-4370

Follow on Twitter @SupplyChainDave

During his career Dave Blanchard has led the editorial management of many of Endeavor Business Media's best-known brands, including IndustryWeek, EHS Today, Material Handling & Logistics, Logistics Today, Supply Chain Technology News, and Business Finance. He also serves as senior content director of the annual Safety Leadership Conference. With over 30 years of B2B media experience, Dave literally wrote the book on supply chain management, Supply Chain Management Best Practices (John Wiley & Sons, 2010), which has been translated into several languages and is currently in its second edition. He is a frequent speaker and moderator at major trade shows and conferences, and has won numerous awards for writing and editing. He is a voting member of the jury of the Logistics Hall of Fame, and is a graduate of Northern Illinois University.