Much has been written about Overall Equipment Effectiveness (OEE) but it is too useful not to revisit some of the key points. OEE is a great way to see the impact of the 6 Big Losses, aka waste, the elimination of which is the goal of lean manufacturing.

The 6 Big Losses are:

1. Breakdowns

2. Setup and Adjustments

3. Small Stops

4. Reduced Speed

5. Startup Rejects

6. Production Rejects

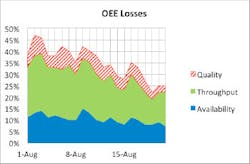

You can calculate OEE at least two simple ways depending on the information you are starting with. The standard formula is: OEE = %A x %T x %Q, where

- %A (Availability) is the ratio of the time the equipment was available for production to the scheduled operating time, and

- %T (Throughput) is the ratio of the actual output to the total possible output while equipment is running, and

- %Q (Quality) is the ratio of good output to total output.

A second method, the Throughput Ratio method, is handy for assessing an overall process or line. OEE = (AT)/(TPR x SOT), where

- AT (Actual Throughput) is the amount of good product produced, and

- TPR (Theoretical Processing Rate) is the processing rate of the system's bottleneck under ideal conditions, and

- SOT (Scheduled Operating Time) is the amount of time the system is not scheduled to be idle (includes production and maintenance).

Here are a few common errors that prevent OEE from delivering its full value as a key performance indicator:

- Not using the ideal equipment speed or cycle time – If you use anything else, such as a budgeted or average rate or speed, you make it difficult to see the real impact that the 6 Big Losses have on performance. You are setting the bar too low.

- Not Including changeover time – This is a common mistake because people argue that changeover is not processing, which is true, but our objective is to improve throughput and every minute spent on changeover is a minute not spent on throughput.

- Not recognizing the bottleneck on a line – The second method for calculating OEE above works well for a production line provided you recognize the bottleneck. It should go without saying that the bottleneck sets the pace for the entire line so the meaningful OEE for the line must be based on the throughput at the bottleneck.

- Focusing on the OEE score and not the underlying problems – Sounds simple but, as is the case with using performance indicators in general, users sometimes forget that the whole point of these indicators is to drive corrective action. When your child’s temperature is 104 you need to act, not simply note that it is 6 degrees too high.

Steve Mueller is director of Commercial Operations for Daniel Penn Associates. He is responsible for project development, management and delivery of results for the company’s private sector clients. He has over 30 years consulting experience.