Outsourcing Does Not Guarantee Superior Warehouse Performance

With more organizations outsourcing some or all of their logistics processes, third-party logistics providers (3PLs) and fourth-party logistics providers (4PLs) have become an important part of the supply chain. These providers offer an increasingly wide range of services that are often customized to the needs of shippers. What remains unclear is the extent to which individual organizations use 3PL/4PL services and how satisfied they are with the services they receive.

To gain insight into these issues, APQC conducted a survey of supply chain professionals. Respondents provided a variety of information, including the types of services they outsource to 3PLs/4PLs and data related to logistics performance. The survey results reveal a surprising gap between the satisfaction of shippers and the logistics performance these organizations achieve. This gap indicates that shippers may not be closely monitoring the performance of their service providers. 3PLs and 4PLs clearly have room to improve service delivery, but shippers should develop closer relationships with providers to facilitate performance improvement.

Degree of Outsourcing

For this article, we focus on the extent to which organizations outsource warehousing and/or distribution centers (DCs) and the effect of outsourcing on warehousing performance. According to the survey results, a majority (73%) of participating organizations outsource warehousing and/or DCs to 3PLs or 4PLs to some degree. Of the organizations that outsource, most report some outsourcing to 3PLs or 4PLs, rather than extensive outsourcing.

APQC also asked survey respondents to rate on a three-point scale their satisfaction with logistics functions outsourced to 3PLs/4PLs. It is worth noting that all the responding shippers are at least minimally satisfied with the performance of their 3PLs/4PLs when it comes to operating warehouses and/or DCs. However, the majority of the respondents that outsource warehousing (57%) are only somewhat satisfied with the performance of 3PLs/4PLs for this logistics function. Forty-three percent are very satisfied with how their providers operate warehousing and/or DCs.

Inventory Accuracy

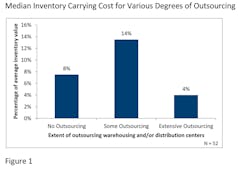

The APQC survey collected data on logistics performance to determine whether organizations that outsource to 3PLs and 4PLs perform better than those that do not. For this article, we focus on inventory carrying cost as a percentage of average inventory value. At the median, organizations that conduct some outsourcing of warehousing and/or DCs have higher inventory carrying costs than organizations that extensively outsource warehousing and/or DCs as well as organizations that do not outsource this function (Figure 1).

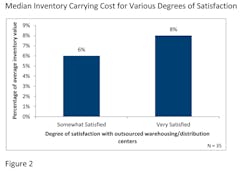

Surprisingly, organizations that report being very satisfied with their providers with regard to operating warehousing and/or DCs have higher inventory carrying costs than organizations that are only somewhat satisfied with provider performance (Figure 2). These results indicate that organizations with a high satisfaction level may not regularly review the warehousing performance delivered by their providers. At the very least, the results show that there is room for the 3PLs and 4PLs to improve.

Information as a Starting Point

For the most part, organizations are happy with how 3PLs and 4PLs manage their warehousing and/or DCs. However, there is room for improvement. Organizations that are very satisfied with the level of service provided by 3PLs/4PLs do not necessarily see that translated into superior performance. Shippers that currently contract with 3PLs/4PLs should take a look at the results delivered by these companies to determine whether to initiate discussions with providers about improving performance. If this is not possible, organizations should consider whether it would be better to move logistics functions to another external provider or back in-house.

Organizations looking to outsource to a 3PL or 4PL should weigh any potential cost savings obtained by outsourcing against the potential for lesser logistics performance. Even if outsourcing does provide initial value, that does not mean an organization can stop paying attention to logistics performance. Close monitoring can help shippers work with providers to improve performance in ways that benefit both parties.

APQCis a member-based nonprofit and a proponent of benchmarking and best practice business research. Working with more than 500 organizations worldwide in all industries, APQC focuses on providing organizations with the information they need to work smarter, faster and with confidence.