Systematizing Continuous Improvement: It's Not About the Methodology or Tools

Implementing an effective and sustainable continuous improvement (CI) program is hard work. It typically requires dedicated effort from multiple operations and CI leaders who, let’s face it, start out at a disadvantage.

Think about it for a moment…all of the work that takes place in a manufacturing operation can be placed in one of two categories: (1) activities required to operate and maintain the plant or (2) activities to improve the way to operate and maintain the plant.

Category one refers to all of the tasks, both proactive and reactive, required each day to ensure that enough first quality product is made to meet the production plan. The focus is necessarily on the short-term and all of the work has to be done with no exceptions.

Category two, the work done to make the operation more efficient or otherwise improve working conditions, while important to the long-term competitiveness and viability of the operation, is rarely viewed with the same sense of urgency as category one, which makes it a prime candidate to get postponed by the so-called “tyranny of the now.”

This natural tendency to deprioritize improvement work represents a significant challenge but fortunately not an insurmountable one. What is required is a systematic approach that embeds improvement activities into the work flow of the plant so that they are routinized in a manner similar to the “operate and maintain” activities.

Introducing a New Mental Model

The most important paradigm shift that needs to occur to successfully embed CI into the DNA of the organization is to change people’s mental model such that they stop thinking of improvement work as a series of largely disjointed or unrelated activities competing for increasingly limited time and resources.

The approach for enabling this paradigm shift can’t be to introduce new CI methodologies (e.g., lean, Six Sigma, TPM, etc.) or tools (kaizens, SMED, kanbans, etc.) into the organization because, as described previously, the lack of priority for CI has little to do with the methodology or tools and a lot to do with the perception that improvement work is of secondary importance or otherwise distracts from more urgent operational matters.

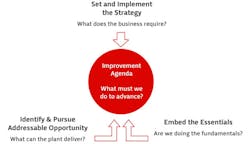

In my experience, there are three key managing processes that are essential to the systematization of continuous improvement. Operations and CI leaders who focus their efforts on entrenching these three managing processes are much more likely to drive sustainable business impact through CI than those who are singularly focused on using the right methodology or tools. These three managing processes are illustrated in the graphic below and discussed afterward.

Few, if any, would argue with the idea that it’s important to define the business strategy and cascade that strategy to the plant level and below…that’s business management 101. Yet, while seemingly everyone agrees that strategy setting is hugely important, few organizations seem to really do it well.

There are at least two reasons why. First, many organizations make it too complicated. A well-defined strategy should simply and succinctly answer one “mega” question; namely, “what does the business require of my operation?” In a manufacturing context, sub-questions to assist in answering the mega question may include:

- What do we need to do different, or better, for the business to be successful?

- Are we growing market share, so the business needs us to produce more?

- Are we trying to hold market share, so the business needs us to lower our cost of manufacture?

- Are we diversifying our product portfolio, so the business needs us to produce a different mix of products?

The point is that simplicity and succinctness should win the day over complexity for the sake of comprehesiveness.

Second, many organizations have not defined and deployed a standard strategy setting method & process. Hoshin kanri is probably the most well known method within manufacturing, but the specific method chosen is less important than getting to a consistent standard both laterally (i.e., across the enterprise) and longitudinally (i.e., across time) because routine is a function of consistency and enables the phenomenon known as “economies of standardization” (i.e., standard processes are less likely to be overlooked, tend to be more efficient, and produce more consistent outcomes than variable processes).

The Gap to Perfect: A Bottom-Up Approach to Opportunity Identification

Unlike strategy setting, which is a business practice that virtually all manufacturing operations know and understand (even if not done well), many operations have never completed a true “gap to perfect” analysis across all critical operational performance categories -- productivity, cost (fixed and variable), quality, maintenance & reliability, etc. -- which means that they don’t really know with a high degree of accuracy what they could deliver to the business under ideal circumstances.

It’s critical to differentiate reporting from analytics. Reporting provides a performance snapshot for a set of measures compared to an agreed standard or target. Analytics is a detailed quantitative and qualitative deep dive in order to holistically compare performance against a perfect or world class standard for the expressed purpose of identifying the biggest operational and financial improvement opportunities, flagging which of those opportunities to pursue, and recommending the best tactics for pursuing them.

Analytics is necessarily more detailed and prescriptive than reporting and is an often overlooked managing process. This is a problem … if an operation doesn’t know how it stacks up against an ideal standard, then how it is to properly gauge what it can contribute to the business through a step change in performance?

Best Practices: The Blocking and Tackling of Operations Improvement

In American football, while all teams have the same goal (i.e., win the Superbowl), each one goes about it in a different way. Some teams are high scoring while others prefer to win with defense and field position. Some teams are built for speed while others are built for power.

However, there are certain fundamental practices that all football teams must establish to be successful. These include sound blocking and tackling, holding on to the football (i.e., no turnovers), avoiding penalties, and knowing the playbook.

These fundamental practices are important regardless of the team’s strategy or game plan and are reinforced and practiced by all teams religiously.

The same concept applies in manufacturing. Namely, there are certain standard best practices that need to be in place under all circumstances. For example, the plant needs to be a safe place to work, the equipment needs to be maintained so that it works when and how it’s supposed to, and employees need to be able to transfer the operation from Shift A to Shift B without disrupting production.

And to continue the football analogy, these practices need to be prioritized and reinforced regularly or they will regress over time. The best run operations have identified, codified, and disseminated these practices and created a platform and process to determine adherence to the standard.

The Improvement Agenda: The Intersection of Three Key Managing Processes

My advice to any business that is struggling to gain traction with their CI program is to set aside all discussions about methodology and tools and focus on driving the three managing processes described above because, once the business is successful in establishing those processes, then two phenomena will occur:

- The improvement agenda for the plant – projects to pursue, performance indicators & targets to measure, and best practices to develop – becomes blatantly transparent to everyone in the operation

- This newfound transparency and alignment will cause plant leaders to stop resisting continuous improvement and, instead, start pulling for the support they need to execute against this agenda

As employees’ mind-sets’ shift away from CI as a distraction and toward CI as a necessary and vital enabler of business performance, then the business can bring the right combination of methodologies and tools to drive sustainable business impact.

Roger Price is the senior director of new business for Phase 5 Group. Formerly P5G’s manufacturing practice leader, Roger is currently leading the effort to develop and commercialize new product-based solutions for current and future manufacturing clients. Roger has led client engagements for DuPont, Land O’ Lakes, NOVA Chemicals, SunCoke Energy, and AB Mauri Food Inc. among others. You can contact Roger at [email protected].