Deep in the heart of Texas, Nabors Industries Ltd. is learning more every day about the largest robot you might ever see.

Nabors is a land drilling contractor, at the top of that industry’s pecking order with more than 200 rigs currently at work around the globe. They dig deep, they dig out, they dig around the clock, and they dig so much that their tech leaders are always looking for something new. They found their latest something new — the Robotic Pipe Handler RPH-3500 from Robotic Drilling Systems — just a little off the beaten path … in Norway.

The RPH-3500 is fully electric, constructed on nine axes, and designed for pipe and casing. It can haul more than 7,700 pounds on each pipe handler boom. Inside a single five-minute stretch, Scott Boone, VP of drilling automation and downhole tools for Nabors and a 34-year industry veteran not prone to hyperbole, described it as “very advanced,” “amazing,” “beautiful,” “phenomenal” and “probably the world’s largest robot.” That last superlative is most definitely warranted. The robot stands more than 70 feet tall, its arm sliding autonomously just about the whole way.

Nabors received its first RPH-3500 from RDS in September 2016, and has “been doing the development work to integrate it into rig intelligent controls” ever since, Boone said. “Having that arm integrated in with a wrench, with the top drive, with the ground handling system — those are all integration systems that had to be worked through. The robotic arm itself does a very good job of working within its space.” The goal is to have its rig “working by the end of this year” — a necessity because Nabors has a whole business plan structured around the robotic import.

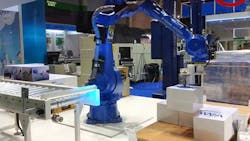

You won’t see the RPH-3500 on many factory floors — at least not vertically — but walk around and you will see more and more industrial robots than ever before, performing more tasks that are more involved and more important to the bottom line.

Where are industrial robots today? Finally back to where we thought they would be in the early 1980s: filling up work stations, moving workers to new tasks and sparking whispers of real workforce change. They are also more collaborative, more efficient and, because favorable aesthetics seldom hurt, generally better looking. Let’s hit the floor.

Keep Your Eyes Peeled and Your Mind Nimble

Variety can be the spice of the life, of course. When applied to industrial robots, it can also spice up a floor.

You can turn to classic names like ABB and Yaskawa Motoman for the sturdiest machines separated into their own cells. You can eye newer companies like Rethink Robotics and Universal Robots for collaborative robots designed to look a little like us (or at least a little like our limbs). You can unleash an autonomous rover from Clearpath Robotics or Fetch Robotics on your floor. The choices range wider than ever before and the ease of use has never been higher.

“Some of the new technologies have made robots a little bit easier to use,” said Jeff Burnstein, president of the Association for Advancing Automation. “You can implement them and have them up and running without a lot of time or resources put into hiring system integrators. Sometimes less floor space is required with these new robots. The promise is that these robots are safer, easier to install, and easier to program — because you don’t really program them, you just move them around.”

The RPH-3500 is not among those easy-to-use newcomers, of course, but many of the robot makers mentioned above — and many more not — are designed with that benefit in mind. You can’t quite plug and play, but you can come close. The rise of collaborative robots has been a bit of a revelation the last few years. Here are some other trends to keep an eye on in 2018:

Collaborative, meet high-speed: The latest challenge for some of the bigger robot makers has been blending collaborative robots with more traditional high-speed models. “The traditional robots working in collaborative mode can run at that speed, but as soon as the people are gone, they can go at a much faster speed,” Burnstein said. “Throughput makes them maybe not suitable for every application.”

Mobile can really get around: Newer names like Clearpath and Fetch have introduced some of the top mobile robots available, self-driving wunderkinds that can open up plenty of new possibilities for your floor, though there is no shortage of competition. Adept Technology, Aethon Robotics, IAM Robotics, Locus Robotics, and Mobile Industrial Robots (or MIR) are all rolling ahead.

Going mobile … with limbs?: More and more, mobile robot makers are pairing their low-to-the-ground creations with an arm, with combined tasks in mind. “The advantage of having a mobile base with an industrial robot arm is for applications like picking high things, right?” Burnstein said. “That’s why companies are interested in it.” The more material handling applications, the better.

Deep learning and artificial intelligence are changing the game: And no, blending robotics and AI isn’t far off. It’s happening now, actually. “Today, most of the inspection tasks can’t be done by a machine’s vision because it takes a level of nuance that’s difficult to capture in a quantitative way,” said John Dulchinos, the former president and CEO of Adept Technology who joined Jabil Circuit in 2013 and is today VP of 3D printing and digital manufacturing. “Deep learning allows us to take the same algorithms Google and Facebook use and apply it to applications where we can have an operator teach the system, and let the system learn where the dividing line is between a good part and a bad part.”

“As robots can teach themselves how to do tasks,” Burnstein said, “that opens up the ability to move along applications more quickly so you don’t have to program every robot to do something. The robot can just learn.”

Inside the German Mutterschiff

Amazon might be the global leader today when it comes to adding robots to its workforce. Now in its third decade overall and its first as an everything retailer, it counts more than 30,000 pickers and runners just at its fulfillment centers. But no matter how high the robot headcount climbs at Amazon or other companies, Volkswagen will always retain a special place for its early adoption and sheer devotion.

Robots are everywhere inside its Wolfsburg mothership — which measures about 70 million square feet and is the largest manufacturing plant in the world. There are almost a thousand Kuka robots just building underbodies in the body shop. A couple thousand more are clustered in cells of four, five, six and seven, all over the sprawling facility — mounted on the floor, on the walls, even on the ceiling. Their synchronous motions around so many cars are a sight.

Industrial robots are an incredible tool, though whether they are incredible for the workers still on the floor remains to be seen. According to a paper published earlier this year by a pair of economists — Daron Acemoglu of the Massachusetts Institute of Technology and Pascual Restrepo of Boston University — the concentration of industrial robots in an area over an almost-two-decade span, 1990 to 2007, was directly related to a drop in jobs and pay. And yet, the number of Americans employed in the manufacturing realm actually increased last year for the first time in what almost literally feels like forever.

What should we think?

More importantly, what should we do?

“People are pretty talented,” Dulchinos said. “It will be difficult to replace a whole operator station with a robot. You can get 70% of it, 80% of it relatively straightforward, and you can take care of the mundane stuff. But there are a lot of nuances that are difficult to replace with a robot.”

About the Author

Matt LaWell

Staff Writer

Staff writer Matt LaWell explores news in manufacturing technology, covering the trends and developments in automation, robotics, digital tools and emerging technologies. He also reports on the best practices of the most successful high tech companies, including computer, electronics, and industrial machinery and equipment manufacturers.

Matt joined IndustryWeek in 2015 after six years at newspapers and magazines in West Virginia, North Carolina and Ohio, a season on the road with his wife writing about America and minor league baseball, and three years running a small business. He received his bachelor's degree in magazine journalism from Ohio University.