Action Learning: Key to Developing an Effective Continuous Improvement Culture

The best methods and the best of intentions can easily fail unless we take into account how adults learn in our organizations. During World War II a process that has become known as Training Within Industry (TWI) and its component Job Instruction (JI) were developed and then adopted by Toyota as it developed its system of production.

For management development Toyota and other Japanese companies added the role of the sensei or coach. These methods are effective because they are consistent with action-learning that recognizes the reality of how adults learn.

Malcolm Knowles, who pioneered the field of adult learning, identified the following principles as critical to adult learning:

- Adults are autonomous and self-directed. They need to be free to direct themselves. Their teachers must actively involve adult participants in the learning process and serve as facilitators for them. They must show participants how the learning experience will help them reach their goals.

- Adults have accumulated a foundation of life experiences and knowledge that may include work-related activities, family responsibilities and previous education. They need to connect learning to this knowledge/experience base.

- Adults are goal-oriented. Instructors must show participants how this class will help them attain their goals.

- Adults are relevancy-oriented. They must see a reason for learning something. Learning has to be applicable to their work or other responsibilities to be of value to them.

- Adults are practical, focusing on the aspects of a lesson most useful to them in their work. They may not be interested in knowledge for its own sake. Instructors must tell participants explicitly how the lesson will be useful to them on the job.

- As do all learners, adults need to be shown respect. Instructors must acknowledge the wealth of experiences that adult participants bring to the classroom. These adults should be treated as equals in experience and knowledge, and allowed to voice their opinions freely.

Another way of saying this is simply to say that adults arent good at sitting at a desk and obediently following instructions and learning theories or abstractions. Learning has to make a difference to them, and they have to put it into action. I think the same could be said for children, but we dont need to argue that point.

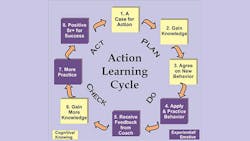

Much of my own training is focused on the development of both work and management teams to engage in effective continuous improvement, problem solving, and to become a high-performing teams. What has proven most effective is to apply this action-learning model to team development. The eight steps illustrated here constitute a cycle of learning and continuous improvement. In many ways they correspond to the PDCA cycle of improvement. However, they are a bit more specific to the actions required for effective learning and incorporate the role of sensei or coach.

The steps illustrated in yellow are primarily knowing/gaining knowledge steps. The steps in purple are more experiential and have more impact on how the learner feels. Knowledge and emotions are equally important in gaining sustained change in individual behavior or in the culture of the organization.

Too often our training methods focus more on knowing, and too little on the emotive aspect of learning, which is more likely to occur from experience. Often we assume that if they know, they will do, and this is a false assumption.

1. Build A Case for Action:

It is essential that team members understand the business case for action. Why do we need to do this? What difference will it make to our performance, to customer satisfaction, and to my own work?

As management embarks on a process of continuous improvement, they need to point to competitors, best practices, financial benchmarks and the voice of the customers who are telling us that we need to improve. And it helps to make clear that learning and practicing the new skills will be a component of everyones appraisal process. In other words, it is the job of managers and coaches to make change matter!

2. Gain Knowledge:

Transferring knowledge is what most corporate trainers do best. It is what classrooms are best designed to accomplish. It is why we have books and websites. However, knowledge very often does not result in behavioral change. It is the difference between taking a history course in which knowledge acquisition is the goal in itself, as opposed to learning to play the guitar. The former is primarily about cognition/knowledge, the latter is about habits or changes in behavior gained through experience and feelings of comfort with that new behavior.

If we are training teams to solve problems effectively, knowing the steps in a problem-solving model is important, but it is only the beginning of employing that knowledge for continuous improvement. Knowledge without action will not change habits or culture.

3. Agree on New Behavior:

Intention is the beginning of change. The guitar instructor may teach a chord position or scale on the fret board. By itself, that is useless knowledge. It only becomes useful when practiced. The student must agree to practice the chords or scales.

The way I have designed my own training manual is so that each chapter is a training module and each training module corresponds to a deliverable a desired performance or behavior. For example, the second chapter is on writing the teams charter. The deliverable or action step is to actually go through the steps in writing the charter and gain approval of the sponsoring manager. Another chapter is on defining customer requirements. Of course, the team then brainstorms customer requirements, interviews customers and agrees on customer requirements. So, each bit of knowledge and training then asks for a new behavior to be performed, the team agrees on the behavior and then takes action.

4. Apply & Practice New Behavior:

Imagine learning to play a musical instrument. How much knowledge of the keyboard or fret board is useful without then putting your hands on the instrument and practicing? The answer is very little. The important learning comes from playing the instrument, hearing the sounds, trying out different positions and chords, and experiencing their difference.

At one point I had the idea that I would learn to play the banjo, and I bought a lesson book by Pete Seeger. When asked how often you should practice his answer was Never. Just play! What he understood was that the learning will come from the joy of playing, not from doing exercises or turning the experience into a painful task.

Learning any new skill is much the same way. Teams need to practice problem-solving and experiment. It is OK to fail as long as every effort is recognized as a learning experience.

Practicing, evaluating, improving becomes a way of life. A Fast Company article (6/2/2009) on Toyotas Georgetown, Ky., plant described the reflection of one worker in the plant: Artrip has been at Georgetown for 19 years. The way he does his work is so compelling it has become part of his personal life. When I'm mowing the grass, I'm thinking about the best way to do it. I'm trying different turns to see if I can do it faster, he says. This is a clear sign that continuous improvement has become ingrained in the culture.

5. Receive Feedback from Coach:

The role of the sensei has become understood as an element of Toyota culture. A sensei is, essentially, a personal coach and mentor. Someone who can guide, observe, and give feedback and encouragement. It is worth noting that in every sport, whether the emphasis is on team performance or individual performance, there is always a coach. And coaches are not reserved for children or new learners. The best professional quarterbacks, tennis stars, professional golfers and opera singers all have personal coaches even though they are at the top of their game.

In a May 2004 Harvard Business Review article (Learning to Lead at Toyota), Steven J. Spear does an excellent job of describing how a new manager is hired and trained at Toyota. His coach introduces him to the organization with structured observation and debriefing on what he sees. He is asked to find improvements, many each day, just from observing. Then he is asked to work on the line with an assembly team. He is asked to find improvements and work with the team implementing them. He is then taken to Japan to again work with a front-line team and implement improvements, even in the very plant where the Toyota Production System began its development.

At each step the sensei is encouraging him, guiding and debriefing with him on the lessons he is learning. It is intensely personal and direct training and coaching. But, the sensei does little instructing in the traditional sense. Rather, he is creating experiences, asking questions, encouraging reflection.

Now consider how you develop teams in your own organization. Do they have a coach? Do they follow a structured learning process? Do they receive guidance, encouragement and feedback from a coach? Let me suggest that this is a necessity for the development of teams at every level of the organization.

6. Gain More Knowledge:

And now, the cycle becomes obvious. After each lesson learned, action or deliverable completed, the team receives feedback from the coach and then goes on to learn the next element of development: how to develop a balanced scorecard; how to map their work process; how to recognize variances of common versus special cause; how to reduce waste and cycle time, etc. And again this leads to practicing those skills.

7. More Practice:

The team and their coach should map out a series of 10 to 20 steps that the team or individual will learn, then do, then gain feedback and reflection. These steps should be those that lead to the complete set of behaviors you want a team to perform.

8. Positive Reinforcement from Coach and the Natural Environment:

As teams practice the skills of continuous improvement they begin to have an impact on actual performance. They should be able to see this impact on measured performance, on graphs. This is in itself positive reinforcement and strengthens the learned behavior.

It is the job of both the coach and the manager to assure that new skills and desired behavior lead to good outcomes for both individuals and teams. These outcomes can be as simple as a certification that you are a high-performing team, or the opportunity to present the results of your efforts to senior managers. There are a hundred ways to make it matter to strengthen the behavior of continuous improvement, and this reinforcement should be part of the designed learning process.

While there is nothing entirely new about the eight steps of this action-learning cycle, it is a key to establishing lean management and culture that is too often overlooked.

Lawrence M. Miller has been doing organizational change consulting for 35 years, beginning with his work creating a free economy in prisons. He has worked with Honda, Shell Oil, and dozens of other corporations. He is the author of nine books, most recently Lean Culture The Leader's Guide. His website and blog is www.ManagementMeditations.com. He can be reached at [email protected].

About the Author

Lawrence Miller

Coach & Author

For the past thirty-five years Lawrence M. Miller has worked to improve the performance of organizations and the skills of their leaders. His expertise is derived from hands on experience creating change in the culture of hundreds of organizations.

He began his work in youth prisons after recognizing that the learning system in the organization had exactly the opposite of its intended effect, increasing, rather than decreasing, dysfunctional behavior. For four years he worked to redesign the prison system by establishing the first free-economy behind prison walls, where each inmate had to pay rent, maintain a checking account, and pay for everything he desired. This was one of the first applications of behavior analysis in the correctional setting.

He has been consulting, writing and speaking about business organization and culture since 1973. After ten years with another consulting firm, he formed his own firm, the Miller Howard Consulting Group in 1983. In 1998 he sold his firm to Towers Perrin, an international human resource consulting firm and became a Principal of that firm. In 1999 he left that firm to focus on his interest in serving non-profit organizations and solo consulting projects.

He and his firm were one of the early proponents of team-based management and worked with many clients to implement Team Management from the senior executive team to include every level and every employee in the organization. The Team Management process created a company of business managers, with every employee focused on continuous improvement of business performance. In addition to directing the overall change process, Mr. Miller personally coached the senior management team of many of his clients.

The implementation of Team Management led to the realization that the whole system of the organization needed to be redesigned to create alignment so all systems, structure, skills, style and symbols support the same goals and culture. From this realization he developed the process of Whole System Architecture that is a high involvement method of rethinking all of the systems, structures and culture of the organization. Among his consulting clients have been 3M, Corning, Shell Oil Company, Amoco and Texaco, Shell Chemicals, Air Canada and Varig Airlines, Eastman Chemicals, Xerox, Harris Corporation, McDonald’s and Chick-fil-A, Merck and Upjohn Pharmaceuticals, United Technologies, Metropolitan Life and Landmark Communications.

Mr. Miller has authored nine books, among them American Spirit: Visions of A New Corporate Culture, which was the text for Honda of America’s course on their values and culture; and Barbarians to Bureaucrats: Corporate Life Cycle Strategies, which draws on the history of the rise and fall of civilizations to illustrate the patterns of leadership and evolution in corporate cultures. Most recently he authored Getting to Lean – Transformational Change Management that draws on the best change management practices such as socio-technical system design, appreciative inquiry, and systems thinking or learning organizations to provide a road map to transforming organizations.He has also authored The Team Guide to Continuous Improvement, a workbook for team leaders and members, the core human process of lean organizations. He has appeared on the Today Show, CNN, made numerous appearances on CNBC, has written for The New York Times and been the subject of a feature story in IndustryWeek magazine.