A Reason to Do Lean and Six Sigma Executives Will Embrace

Early in my career, some 30 years ago, I had a conversation with my boss that went something like this:

Boss: “Yeah, Dyer, what do you want now?”

Me: “I was reading in the latest issue of IndustryWeek magazine (the company provided subscriptions to all of the engineers) that in Japan, they are now using teams of shop-floor employees to help them solve their quality problems. I think we should give this a try.”

Boss: “What!?! Take shop employees out of production so they can work on problems? That is the dumbest thing I ever heard. We pay our employees to use their hands to make stuff, not think! (Yes, this was actually said back then) Isn’t solving problems why we pay you engineers? What would be the benefit of taking people off the shop floor?”

Me (somewhat naïvely): “Think how much morale will be boosted if the employees have a say in how their processes are improved.”

Boss: “Improving morale and a quarter will buy me a cup of coffee. Now, get out of my office and back to work!”

A few weeks later, I gave it another try.

Me: “Boss, I have been thinking about your question of what the benefit would be to the company for using teams of workers to solve problems. The people who do the work are closest to the problems and will have ideas on how to fix things. By reducing our defects, our customers would be happier with our products and service. That would lead to more sales!”

At this point, my boss tossed me a thick report. On the cover was a chart with bars getting taller each month.

Boss: “See that report? That shows our backlog. It keeps growing, so our customers already love our product. We don’t need to make them any happier. Now, get out of my office…”

Me: “I know… get back to work.”

After several more weeks of pestering my boss, he finally gave in and allowed a team to be formed of engineers and shop-floor employees. We met several times and started solving some major quality issues that had been plaguing us for years. This team was having a real impact and then we hit a brick wall. The people who repaired our defective product (the highest paid position in production) became fearful that if we fixed too many quality problems, they would be out of a job. So, they put pressure on the workers to stop attending the improvement meetings. The team was disbanded shortly thereafter.

Boss: “Told you this was a bad idea. But the brass upstairs heard about the progress your team made in reducing quality defects and wants to know if you would be interested in digging deeper into this whole “team-based problem-solving” approach?”

Ten years later, after having the opportunity to benchmark several companies that were excelling in making improvement happen, attend classes taught by Dr. W. Edwards Deming, Brian Joiner, and Steven Covey, and completing the original Six Sigma training at Motorola University, my answer to “What is the benefit?” had changed considerably.

The example that follows is based on what happened next.

“Ok. Everyone settle down and find a seat. We need to get this staff meeting started,” said Jim Brown the new leader of the XYZ business unit. “I want to introduce a friend of mine, Jane Robinson, from corporate who I have invited in to help us with our output problem. As you all know, our backlog has been growing steadily for over a year, and it does not appear to be getting any better. We need some help in figuring out how to deal with this situation.”

After all of the introductions were complete, Jane asked the following: “So, what is the capacity of your system to produce product on a daily basis?”

“Well. We have made over 2,300 units in a day,” said the director of operations.

“Ok. The demand for your product seems to be around 1,800 a day,” said Jane. “So, why is the backlog growing?”

“We don’t hit 2,300 very often,” said Jim. “Our daily output seems to be all over the place. I am not even sure we know what our daily average is, especially when we factor in the fact that the first few days of every month, the output drops significantly.”

“That is because we drain the supply chain in order to try and hit the end of the month production targets,” said one of the production line leaders.

“Do you have the output numbers for the past several months?” asked Jane. “I would like to put the data on a control chart to better understand how much variation there is in the numbers.”

“Isn’t a control chart used to track variation in product quality?” asked Jim.

“Actually, it can be used to analyze any form of random data,” said Jane. “And it sounds like your data is pretty random.

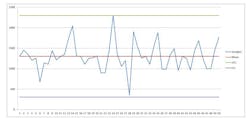

After the information was gathered, Jane created a control chart and presented the results at the next staff meeting.

After passing out the chart, Jane went to the white board and wrote the following:

“So, based on this chart, the most output we can guarantee (within reason) to our customers in a day is only 300 units, and since the average (mean) is only 1,300 units, it is easy to see why the backlog continues to grow. So, we have two issues according to this data. One, the output has way too much variation. It is impossible to know from day to day how much product is going to be sent to our customers. This variability must be wreaking havoc on our supply chain. And, two, we clearly have a lot of capacity leaks causing the average to be significantly below what our customers need.”

“Capacity leaks? What do you mean by capacity leaks?” asked the director of operations.

“There are many examples I have already seen of capacity leaks in this facility,” said Jane. “The easy ones to identify are related to the constraint or bottleneck of our system. If the bottleneck is ever starved of parts or has a quality issue or is not running for whatever reason, we lose system capacity that can never be recovered. After the bottleneck, if a part is scrapped or we make something that is not needed, that will also cause capacity leaks.”

“So, how do we stop all of these leaks?” asked Jim.

“We need to immediately begin training our employees in the tools and methodologies of lean and Six Sigma and begin forming improvement teams; one per process that impacts the output of our system,” said Jane.

“Wait a minute!” exclaimed the director of operations. “We already can’t keep up with demand and you want to take people away from their work stations? That is going to cause us to get even further behind.”

“Look,” said Jim. “We have to do something and do it soon if we want to keep our customers. They are sticking with us for now, but complaints are starting to increase. So, I will take full responsibility for any negative impact to output as we do the training and team meetings. Also, I want to review these output charts with all of our employees and post weekly updates so every employee can keep up with our progress.”

Several months passed, the training was completed, and employee teams were formed. All of the employees were taught the importance of identifying and eliminating "capacity leaks" using the lean and Six Sigma tools. Large scoreboards were installed so employees could see, in real time, how they were doing with key safety, quality and output metrics. The first time they finished the day with zero safety issues, 100% good quality, and made 100% of the daily schedule, the entire plant erupted in applause and cheers.

“Ok, everyone find a seat and let’s get started,” said Jim to his staff. A year had passed since their first meeting with Jane. “Do you have the latest graph showing our output?”

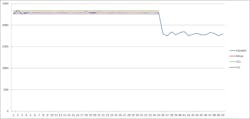

The director of operations presented the following chart:

“Looks like there has been significant improvement in the variability of the output of our system,” said Jane. We can now guarantee over 2,250 units a day to our customers.

“Wait, what happened? Why did our output drop a few days ago?” asked Jim.

“We are all caught up,” beamed the director of operations. “No more backlog. So, now we are only making what our customers order.”

“Hmmm…” thought Jim. “It seems I need to go to the sales group and see what we can do to get demand up.”

“Shouldn’t we start the process of laying off a quarter of the workforce?” asked the director of finance. “We owe it to our parent company to cut our costs and clearly, we no longer need so many workers.”

“Wait a minute!” exclaimed Jane. “The workforce you want to get rid of is what saved our bacon. If we lay off a single person, then don’t expect to get another idea for improvement!”

“No, we won’t start laying anyone off,” said Jim. “Our current profit margin is about 10%. Think about this… we know we have the people and equipment to make up to 2,250 consistently. So, for every unit we sell above our current average demand rate of 1,800, the only additional cost is the raw material and a little bit for power and supplies. The equipment, overhead and labor costs are already absorbed. So, the profit margin on these additional units will be over 40%! We could run a special price cut for our best customers and still produce margins three times the current rate. What a fantastic opportunity! This would not have been possible without a stable, predictable system.”

The Grand Slam Home Run of Improvement

So, back to the question at the beginning of the article… What is the actual, demonstrated output of your organization’s system (production parts or service hours)? If your system of producing product or services is unpredictable, then finding the bottleneck becomes difficult. And, if the system’s constraint cannot be easily identified, then it is nearly impossible to know how your capacity matches up with current customer demand (See article “Understanding the Demand/Capacity Curve” for more information). So, the idea of getting rid of waste needs to be expanded to “How do we get rid of ‘capacity leaks’ to create stable, predictable systems?”

Once this is done, then the order fulfillment team can sit down with the sales and marketing organization and discuss growth strategies that can actually be planned. The profit margins on this additional output (assuming the product or service can be sold) will be amazingly high. Or, another way to think about the results is that the sunk costs will now be spread over a larger quantity of parts, resulting in lower total costs per unit sold. This will generate excitement and support with the business leaders.

What about the systems that have mixed models, seasonal demand and other unpredictable inputs? Some of these are valid concerns and will make it more difficult (but not impossible) to create a predictable system. However, some of this "chaos and complexity" is self-inflicted. When your company leaders do their strategic plans each year, how much time do they spend discussing ways to de-complex their order fulfillment system? For example, one company that swore it was a seasonal producer, supplied product to schools and universities that only did retrofits during the summer months (or so the manufacturer believed). The leaders decided to launch a lean and Six Sigma initiative as part of their business strategy. When they were able to reduce the delivery times from 10 weeks to two days, their customers started buying product throughout the year because they could begin planning retrofits on the weekends. This smoothed their demand considerably.

Keep in mind that these principles also apply to service providers. Recently, I had the opportunity to spend several days in a major downtown hospital. The doctors and nurses were amazing and the care could not have been better. However, when it came time to be discharged, it took over five hours. The hospital was full with several patients waiting for open rooms. This five-hour "capacity leak" gets multiplied many times each day, resulting in the equivalence of several rooms of capacity being wasted.

Equipment Utilization

Finally, for those of you who have kept up with my articles for IndustryWeek, you know that one of my pet peeves is using employee and equipment utilization as key metrics. In fact, I have proclaimed that if utilization is one of your company’s metrics to indicate order fulfillment performance, then lean will never be a reality. However, in a system that produces a stable, predictable output, employee and equipment utilization is actually an indicator as to how demand is holding up. So, as more companies have successful lean and Six Sigma initiatives, the idea of measuring utilization needs to be updated and shifted from operations to tracking the impact of sales and marketing.

A better metric for operations to track is "linearity." Linearity is an indicator of what percentage of the schedule did you actually build that day (both volume and model mix). If your company achieves "make to order" status, then linearity is a critical piece of data to track. And, if linearity stays near 100%, then several other key metrics, such as on-time delivery, will also be robust.

The idea of identifying capacity leaks fits with lean tools such as value stream mapping. As teams map their processes and identify non-value-added steps, they can also identify where "chaos and complexity" is occurring resulting in capacity leaks. Once these leaks are reduced or eliminated, a stable system begins to emerge, making it much easier to plan ways to meet your customers' needs (and create amazing profit margins). That is a reason for making lean and Six Sigma a part of your company’s strategic plan your leaders will enthusiastically support.

John Dyer is president of the JD&A – Process Innovation Co. and has 28 years of experience in the field of improving processes. He started his career with General Electric and then worked for Ingersoll-Rand before starting his own consulting company. Dyer can be reached at (704)658-0049 and [email protected]. See his LinkedIn Profile. He is on Twitter: @JohnDyerPI.

About the Author

John Dyer

President, JD&A – Process Innovation Co.

John Dyer is president of JD&A – Process Innovation Co. and has 32 years of experience in the field of improving processes. He started his career with General Electric and then worked for Ingersoll-Rand before starting his own consulting company.

John is the author of The Façade of Excellence: Defining a New Normal of Leadership, published by Productivity Press. He is a frequent speaker on topics of leadership, continuous improvement, teamwork and culture change, both within and outside the manufacturing industry.

John is a contributing editor for IndustryWeek, and frequently helps judge the annual IndustryWeek Best Plants Awards competition. He also has presented sessions at the annual IW conference.

John has an electrical engineering degree from Tennessee Tech University, as well as an international master's of business from Purdue University and the University of Rouen in France.

He can be reached by telephone at (704) 658-0049 and by email at [email protected]. View his LinkedIn profile here.