Push vs. Pull Manufacturing: Is a Kanban Pull System Right for Your Company?

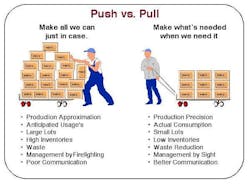

As a manufacturer, you need to make what your customers want. The challenge is knowing exactly what they want, when they want it. In general, approaches to supply chain management in manufacturing include a push system or pull system, but how do you know which is the best for your company?

Push: No Limits on WIP or Dependency on DemandIf you use a demand forecast that drives the Material Requirements Planning (MRP) process to ensure that materials are available for production while maintaining the lowest possible inventory, you are relying on a push-based manufacturing strategy. The forecast may not always be accurate so you may end up with excess inventory, especially when shifts occur in lead times.

There is a time and place for push manufacturing, especially when you manufacture complex, high variety products and tend to have a lot of work in progress (WIP). Push production environments tend to be characterized by long lead times and/or make to stock (MTS) situations. Processing large batches of items at a maximum rate, based on forecasted demand, then moving them to the next downstream process or into storage.

Pull: Limited WIP and Focus on Demand

The goal of a pull-based lean manufacturing environment is to make nothing until there is demand. Finished goods are not produced without a specific customer order. Replacements for intermediates and materials are not acquired before existing items have been used. Pull manufacturing works best when demand is high and steady for a relatively small variety of products.

Push, Pull, or a Combination of Both?

Both these approaches have advantages and disadvantages. In a world of shrinking product cycles, product proliferation, global competition, mass personalization, and volatile demand, you need strategies and tools to support more efficient and effective performance. MRP’s forecast-driven approach alone may not be up to the task, given its tenuous ties to demand. By the same token, pull-based lean manufacturing means you need to be constantly on top of demand. A combination of the two might be the best approach.

Key characteristics of pull-based lean manufacturing and how manufacturers plan their purchasing and production in that environment include:

● Ensuring a continuous flow of production from raw materials to finished products by buffering critically constrained resources to maintain full utilization and establishes supplier relationships and supply management practices that synchronize delivery of raw materials (and sub-assemblies) to the point of use at the time of production.

● Enabling faster throughput, shorter manufacturing lead times, and reduces the amount of inventory needed to support customer service objectives lowering production costs. Limits WIP (work in progress) inventory levels.1 Just-in-time (JIT) material deliveries and demand-pull scheduling reduce the incidence of excess inventory.

● Relying heavily on Kanban manufacturing to signal upstream workcenters to start producing parts. It is equivalent of a work order. The upstream station does not start producing parts until it receives a signal. In this way, Kanban signals control the movement of raw materials and semi-finished products through subsequent workstations. Note that not all Kanbans on a production line will of the same size—they depend on the nature and usage of the part.

● Accounting for cycle time intervals using buffer—the time it takes production to shift back to making a part after making other parts. The buffer also accounts for transportation time, safety stock, seasonality, and promotions. Finally, the buffer puts a cap on the amount of WIP in the system and enables the start of continuous improvement initiatives to reduce lead times through setup and batch-size reduction.

With a pull-based lean environment, you can deliver on-time, meet customer demand, and improve the reliability of your supply chain. Get more insights by reading the white paper: Gaining Operational Control: Lean, Mean, or Somewhere In Between.